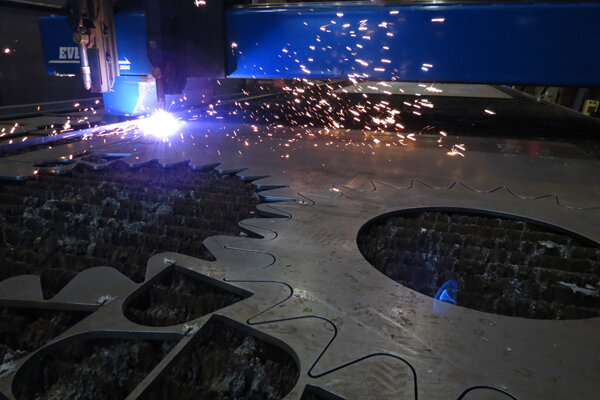

Hi-Def Plasma + Flame Cutting

Hi-Def Plasma

Up to 2” Thick

Hi-Def Plasma cutting is an accurate and cost-effective method used to cut a variety of metals. Due to plasma’s flexible nature, it is extremely effective at cutting with exceptional precision and speed. In addition to its precise cuts, plasma provides a smooth, clean edge. Our plasma tables are capable of cutting profiles up to 10’ wide and 48’ long.

Flame Cutting

Up to 10” Thick

This process uses Acetylene combined with Oxygen to heat steel to extreme temperatures. Using our experience and expertise, our qualified team members can cut steel up to 10” thick. Our cutting tables can use up to 6 torches at once - increasing production which saves you time and money. Our tables are capable of cutting profiles up to 10’ wide and 48’ long.

Additional Services

We have alliances with many local fabrication and machine shops, allowing us to provide additional services such as beveling, forming, rolling and machining. If you need it, Terra Nova Steel can make it happen.